10 Signs, that your Production Needs Collaborative Palletizing

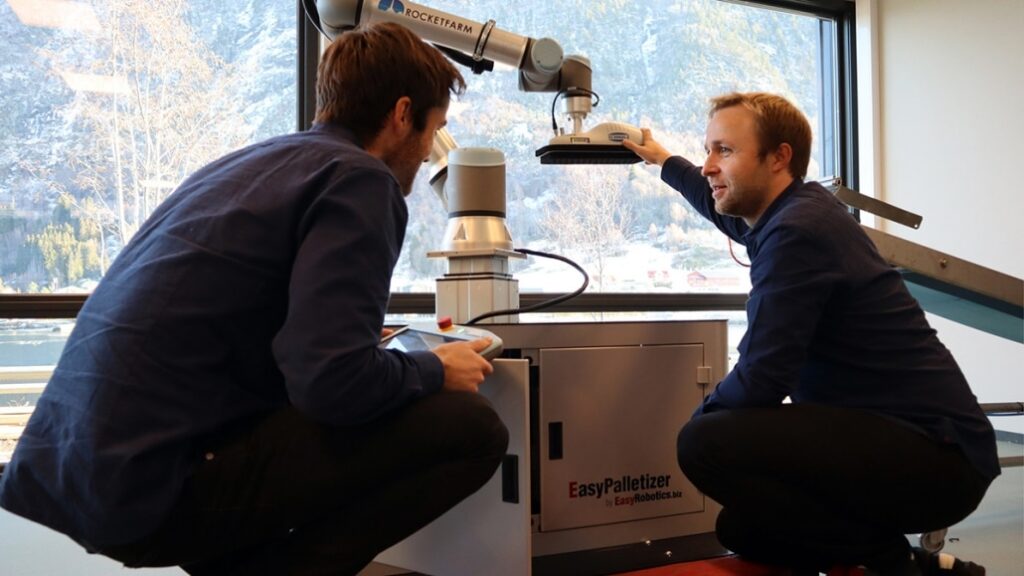

Collaborative palletizing robots, or cobots, are a cutting-edge technology that can help small and medium-sized enterprises (SMEs) to streamline their production processes, reduce costs, and increase productivity. However, not every production will benefit from the use of cobots. In order to determine if cobots are right for your production, it is important to understand the signs that indicate that your production needs this technology.

How to understand the need of use of collaborative robots in palletizing?

As a business owner, here are the steps you can take to determine if your business is suitable for cobot palletizing:

- Assess your current production process: Evaluate your current production process, including the tasks involved, the equipment used, and the personnel required. This will give you an understanding of the areas where cobots could potentially be used to improve efficiency and productivity.

- Identify repetitive tasks: Identify the tasks that are repetitive and time-consuming, as these are the tasks that cobots are best suited to handle. This could include palletizing products, assembly tasks, or material handling.

- Analyze labor costs: Evaluate your current labor costs and assess how cobot palletizing could impact them. Cobots can help to reduce labor costs by freeing up human workers to focus on higher-value tasks and by reducing the need for manual labor.

- Consider quality control: Consider any quality control issues you may be facing and how cobot palletizing could impact them. Cobots are designed to work with high precision and accuracy, reducing the risk of errors and improving the overall quality of your production process.

- Analyze the workspace: Evaluate your production workspace and determine if there is adequate space for a cobot palletizing system. Cobots are highly flexible and can be integrated into a variety of production environments, but it’s important to ensure that you have enough space for the system to function effectively.

- Consider the skills of your workforce: Assess the skills of your current workforce and determine how cobots could impact their roles. Cobots can help to reduce the need for manual labor, but it’s important to ensure that your workers have the skills to operate and maintain the system effectively.

- Research cobot solutions: Research different cobot solutions and assess how they align with your production needs. This could include considering the size and capabilities of different cobot models, as well as the support and maintenance options available.

- Consult with experts: Consult with experts in cobot palletizing, such as system integrators or robotic technology providers, to get a better understanding of the benefits and limitations of cobot palletizing for your business.

By following these steps, you can gain a better understanding of whether cobot palletizing is suitable for your business, and how it could impact your production process, labor costs, and quality control.

Signs, pointing to the need of collaborative palletizing

After the analysis is done, you need to check with the signs pointing to the need of collaborative palletizing. Here are 10 signs that you should consider:

1. Repetitive Tasks

If your production involves repetitive tasks, such as palletizing products, then cobots may be an excellent solution. Cobots are designed to perform repetitive tasks quickly and accurately, freeing up human workers to focus on other tasks.

2. High Labor Costs

If you are facing high labor costs, then cobots may be able to help. By reducing the need for manual labor, cobots can help SMEs to reduce their labor costs and increase their overall profitability.

3. Quality Control Issues

If you are struggling with quality control issues, then cobots may be able to help. Cobots are designed to work with high precision and accuracy, reducing the risk of errors and improving the overall quality of your production process.

4. Health and Safety Concerns

If you have concerns about the health and safety of your workers, then cobots may be able to help. Cobots are designed to be safe for human workers to be around, with sensors and programming that allow them to detect the presence of humans and adjust their movements accordingly.

5. Limited Space

If you have limited space in your production facility, then cobots may be an excellent solution. Cobots are highly flexible and can be easily integrated into existing production processes, even in limited spaces.

6. Difficulty Hiring and Retaining Workers

If you are struggling to hire and retain workers, then cobots may be able to help. Cobots can help to reduce the need for manual labor, making it easier to find and retain workers.

7. Need for Flexibility

If you need to be able to adapt to changing production environments, then cobots may be an excellent solution. Cobots are highly flexible and can be easily scaled up or down to meet the changing needs of the production environment.

8. Inefficient Processes

If you have processes that are slow and inefficient, then cobots may be able to help. Cobots are designed to perform tasks quickly and accurately, reducing the need for manual labor and increasing efficiency.

9. Product Damage

If you are experiencing product damage, then cobots may be able to help. Cobots are designed to work with high precision and accuracy, reducing the risk of errors and improving the overall quality of your production process.

10. Need for Improved Logistics

If you need to improve your logistics and shipping processes, then cobots may be able to help. Cobots are designed to perform tasks quickly and accurately, reducing the need for manual labor and improving the overall efficiency of your production process.

These 10 signs indicate that your production may benefit from the use of collaborative palletizing robots. By understanding these signs, SMEs can determine if cobots are right for their production and make an informed decision about their use.