|

Product order overview

|

|

PFX-1010-03

|

PF X 3x 60kg tray w. Mechlock

|

H: 1050 mm, W: 980, L: 920, Wt: 320 kg, 3x 350x550mm tray area, T-Pad bracket, Compartment for controller, 2,5mm deflection at 60kg/tray, Max part height 240mm, Mech-lock

|

|

PFX-1011-03

|

PF X 3x 60kg tray w. Airlock

|

H: 1050 mm, W: 980, L: 920, Wt: 335 kg, 3x 350x550mm tray area, T-Pad bracket, Controller compartment, 2,5mm deflection at 60kg/tray, Max part height 240mm, Air-lock

|

|

PFX-1010-06

|

PF X 6x 60kg tray w. Mechlock

|

H: 1050 mm, W: 980, L: 920, Wt: 365 kg, 6x 350x550mm tray area, T-Pad bracket, Controller-compartment, 2,5mm deflection at 60kg/tray, Max part height 120mm, Mech-lock

|

|

PFX-1011-06

|

PF X 6x 60kg tray w. Airlock

|

H: 1050 mm, W: 980, L: 920, Wt: 380 kg, 6x 350x550mm tray area, T-Pad bracket, Compartment for controller, 2,5mm deflection at 60kg/tray, Max part height 120mm, Air-lock

|

|

PFX-1100-05

|

PF X 5x 120kg tray w. Mechlock

|

H: 1050 mm, W: 980, L: 920, Wt: 415 kg, 5x 550x350mm tray area, T-Pad bracket, Controller compartment, 2,5mm deflection at 120kg/tray, Max part height 160mm, Mech-lock

|

|

PFX-1101-05

|

PF X 5x 120kg tray w. Airlock

|

H: 1050 mm, W: 980, L: 920, Wt: 430 kg, 5x 550x350mm tray area, T-Pad bracket, Controller-compartment, 2,5mm deflection at 120kg/tray, Max part height 160mm, Air-lock

|

|

PFX-1100-10

|

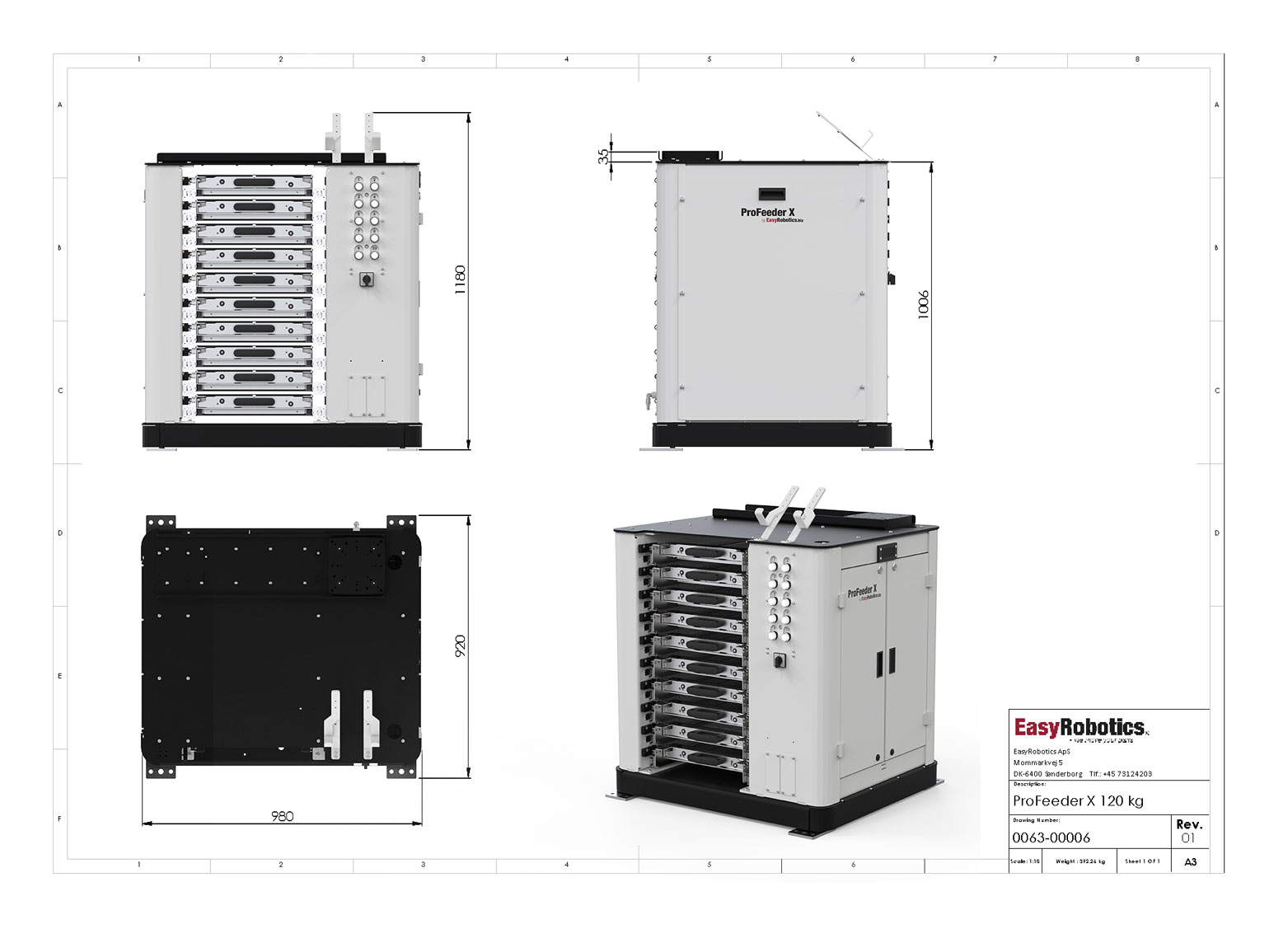

ProFeeder X 10x 120kg tray w. Mechlock

|

H: 1050 mm, W: 980, L: 920, Wt: 535 kg, 10x 350x550mm tray area, T-Pad bracket, Compartment for controller, 2,5mm deflection at 120kg/tray, Max part height 80mm, Mech-lock

|

|

PFX-1101-10

|

ProFeeder X 10x 120kg tray w. Airlock

|

H: 1050 mm, W: 980, L: 920, Wt: 550 kg, 10x 350x550mm tray area, T-Pad bracket, Controller-compartment, 2,5mm deflection at 120kg/tray, Max part height 80mm, Air-lock

|