Logistics automation with collaborative robots and robotic cells

Human-robot cooperation is not only the future of efficient logistics automation, but also the present. Modern cobots are able to significantly simplify the palletizing process, increase its speed and quality. It’s also freeing staff from manual labor and the owner from unnecessary costs.

Having at your disposal the right equipment for logistics automation, you do not have to hire expensive specialists to set it up or reprogram. The simplicity of the interface, equipped with three-dimensional visualization, and intuitive control will allow even an inexperienced operator to quickly reconfigure the robot.

Thanks to the expanded functionality and the presence of intelligent sensors, the collaborative platform is completely safe for the personnel who are nearby, and at the same time, extremely effective.

The result of its work will be perfectly assembled pallets, laid according to a given pattern, up to 2.4 meters high! At the same time, the participation of the operator will be minimal: after adjustment, he has to monitor the continuous process, controlling only the timely change of pallets.

Cobot automation of palletizing application in Grundfos

Robotics in logistics – advantages of cobot automation

The role of robotics in logistics nowadays is huge.

Cobot automation can provide business with the same, or even better quality of palletizing at a lower cost than human workers.

Let`s take a closer look at cobot automation advantages:

- Versatility: you can design the robot to perform any process in logistics, removing the need for repetitive tasks or dangerous work.

- High quality: when you combine robotics with automated inspection equipment, it is possible to guarantee the absence of errors in the performance of tasks.

- Lower risks: robotic automation reduces the risk of human injury. Robots are much safer than humans when performing dangerous tasks. And they can be programmed to perform repetitive tasks that require extreme precision, like high and heavy pallet handling.

- Accuracy: cobots can be more accurate than human workers in most cases. For example, humans are prone to making mistakes due to fatigue, bad weather conditions, or poor work conditions. A robot can perform any task flawlessly.

- Rare maintainance: cobots require less maintenance than a conventional industrial robots. They don’t require routine maintenance like lubrication, and they are ideal for almost any warehouse.

- High compatibility: cobots are highly compatible with many different accessories, like robot cells, pedestals and tables (especially popular cobot brands like Universal robots, Doosan, Fanuc etc.), and can easily be reattached and regrouped for new tasks.

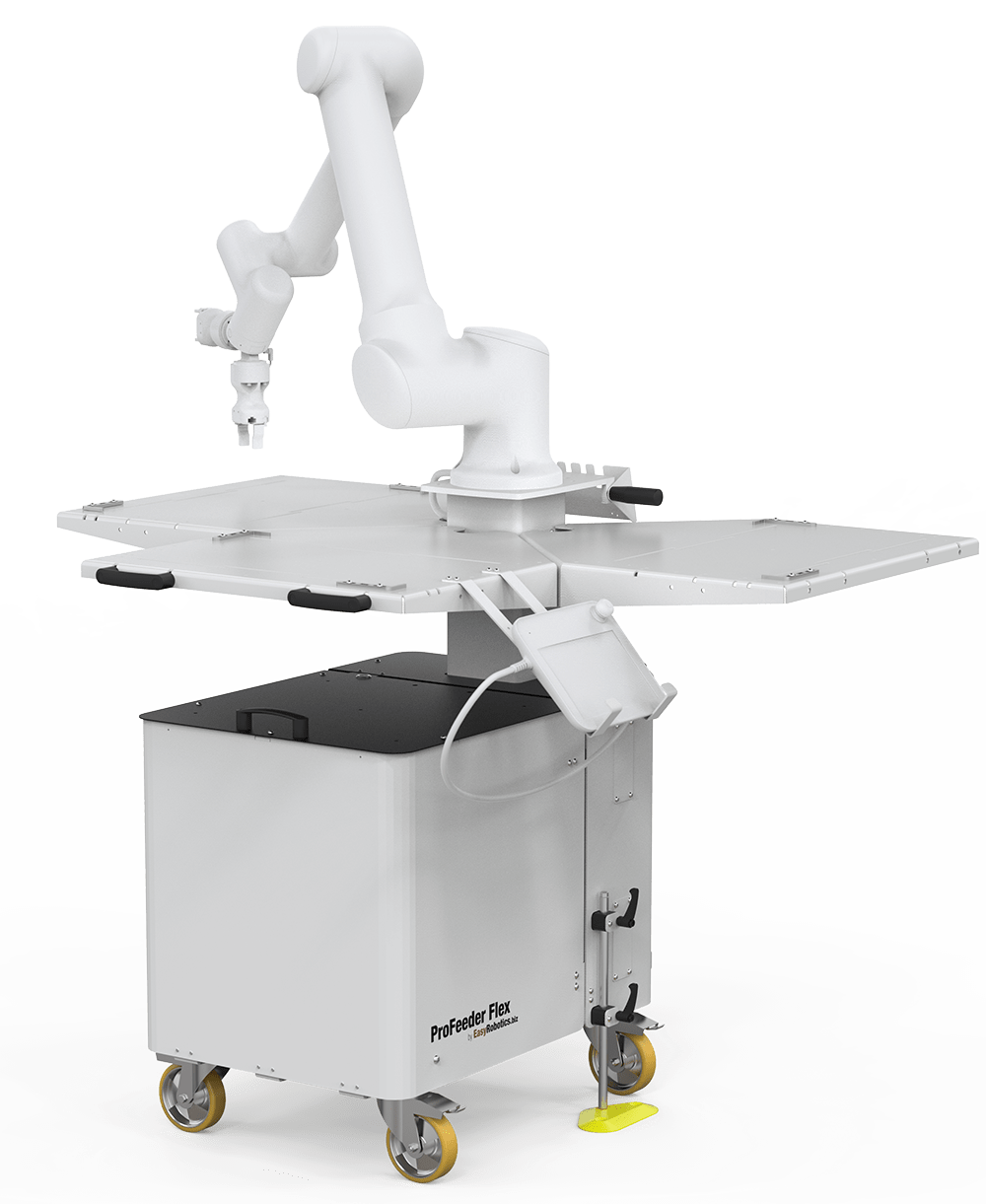

- High mobility: Cobots usually have smaller footprint and higher mobility then traditional industrial robots.

EasyPalletizer – efficient automation of logistics

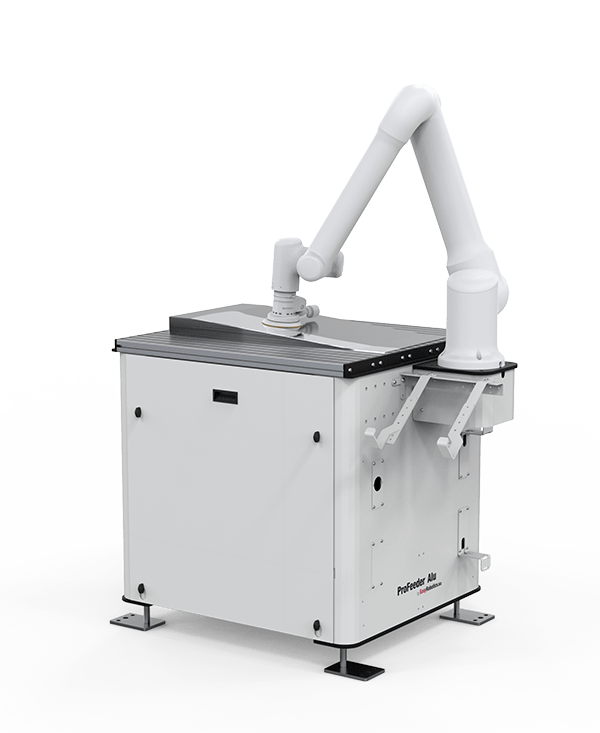

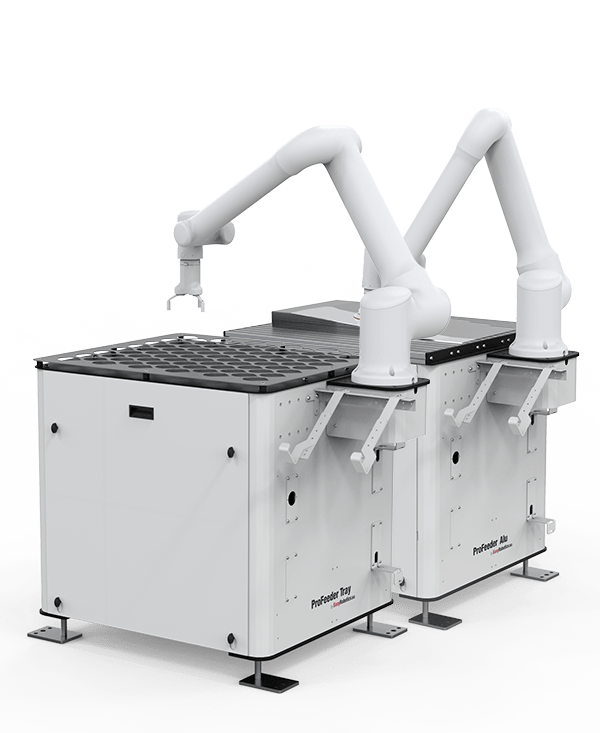

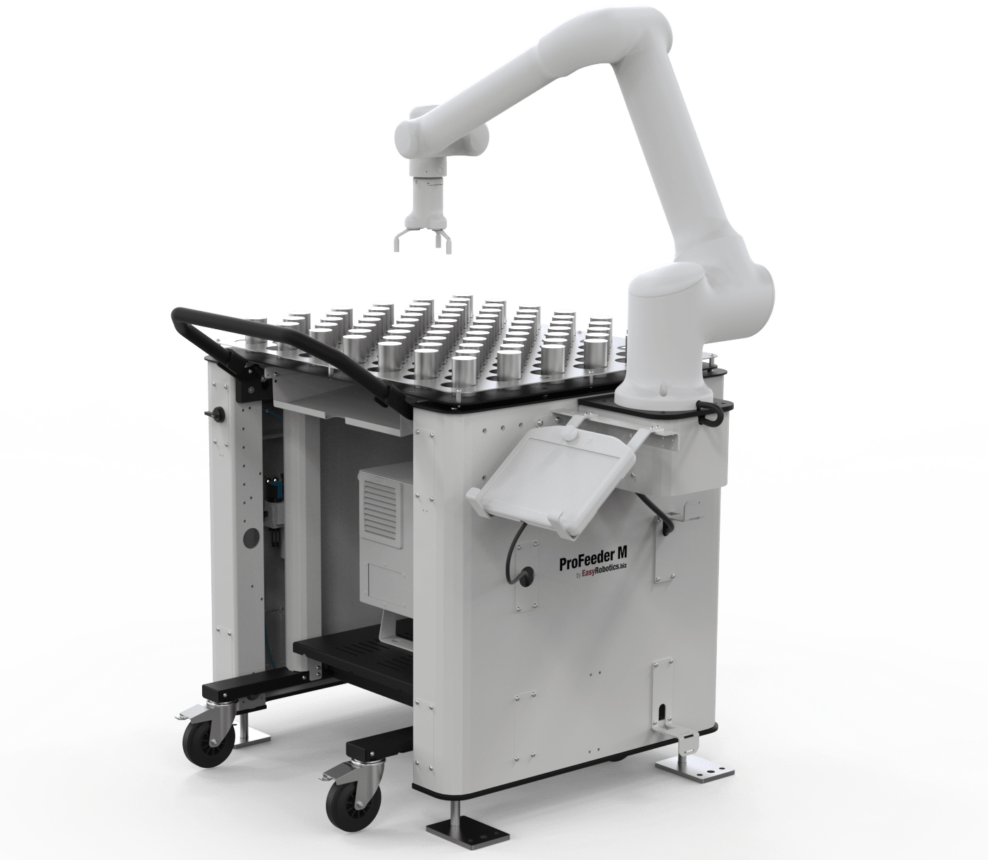

With the help of the EasyPalletizer, you can palletize any cargo in automatic mode. Thanks to its compactness, optimal weight, advanced functionality and built-in intelligence, EasyRobotics cells will become indispensable helpers for your business.

Equipping logistic processes with a cobots and robot-cells, you get:

- Continuous stacking of products according to a predetermined pattern;

- The ability to form stable pallets, which is achieved through built-in control of the correct placement of pallets;

- No need to hire additional employees with skills in programming production equipment. Collaborative robots from EasyRobotics are available for anyone to customize and control;

- Safety and injury reduction;

- Reduction of the payroll due to the full automation of the palletizing process and a quick return on investment;

- High speed of work without loss of quality;

- The ability to move equipment between lines.

It is also worth paying attention to the technical characteristics of EasyPalletizer platform, which play an important role in palletizing efficiency and speed of production.

Features of robotic cells from EasyRobotics:

- Compact dimensions to reduce the footprint;

- High productivity: the collaborative robot is capable of stacking up to

- 8 boxes per minute;

- Intuitive interface for easy installation, assembly and configuration;

- Optimal cell weight, designed taking into account the forthcoming loads, which is 300 kg excluding the lift and the robot.

The EasyPalletizer platform is an innovative solution for your business that can turn the idea of complete logistics automation into reality.

And this, in turn, will:

- Help to reduce costs,

- Increase the efficiency of the palletizing process,

- Add benefits to the company itself and increase income.

For more information, including the terms of purchase and selection of equipment, you can contact your regional distributor or write to us. Our experts will be happy to provide qualified assistance to each client.