Assembly automation through the implementation of collaborative robots and cells

The competition in the manufacturing of various products is growing every day, stimulating an increase in the level of unspoken standards. In such a situation, business owners are simply forced to look for new ways to improve production’s speed and quality, one of which is assembly automation.

How to implement assembly automation in your business? Implement collaborative robots into production step by step, starting with automation of a separate processes – for example, assembly or palletizing. A tandem of cobot and multifunctional robot-cell is able not only to improve the quality of finished products, but also to significantly speed up the assembly process, freeing personnel from monotonous manual labor.

Moreover, collaborative robots, unlike hired staff, can work 24 hours a day without interruption. They are not influenced by the so-called “human factor”, which leads to errors and, as a consequence, poor-quality of assembly. The cobot will work strictly according to the specified program without interruptions. The operator will only have to observe the process and reconfigure the equipment if necessary.

It is not difficult to reprogram the collaborative robot. With an intuitive interface, setup takes minutes. Cells complementing collaborative robots are, in most cases, shipped 80% assembled. Due to this fact, it’s possible to quickly assemble cobot and start using them almost immediately.

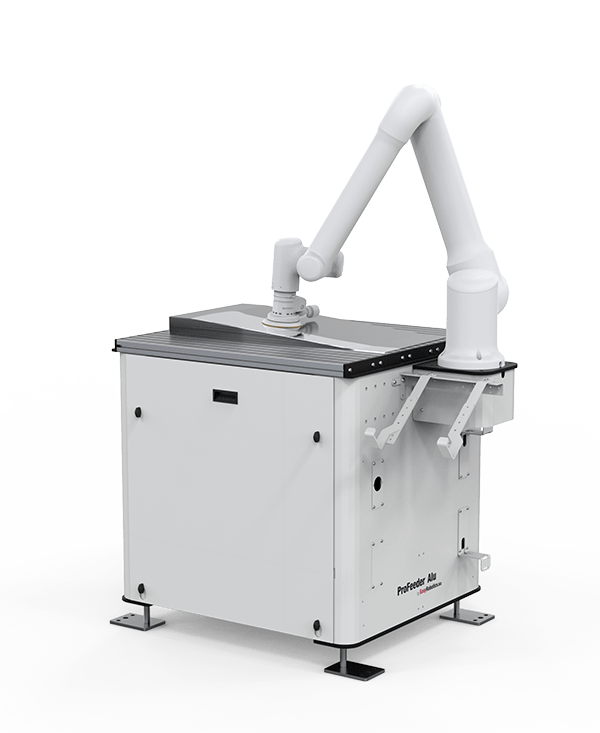

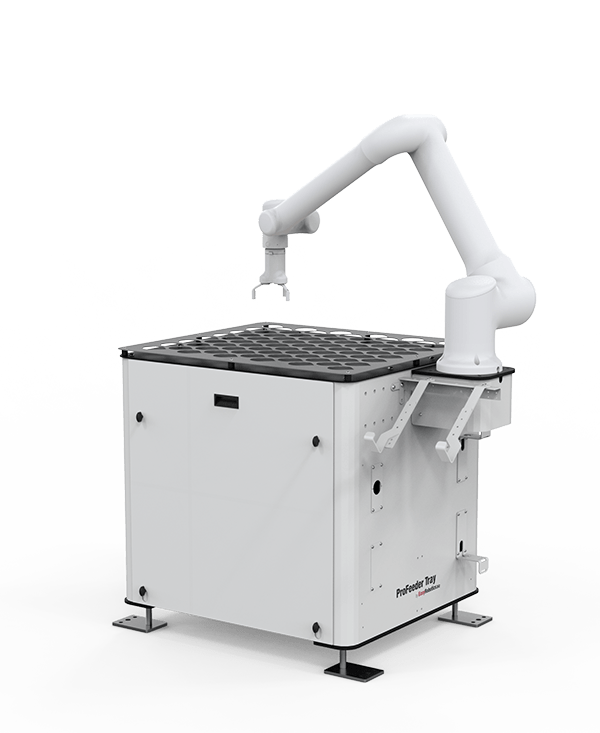

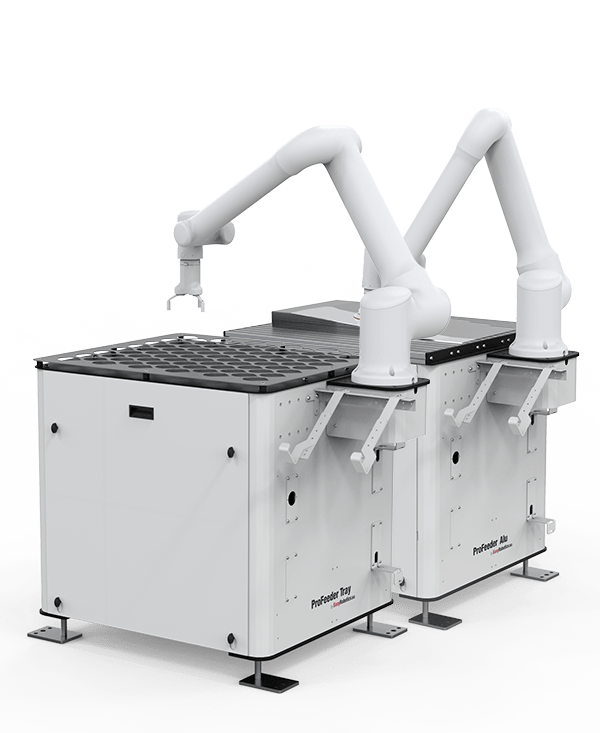

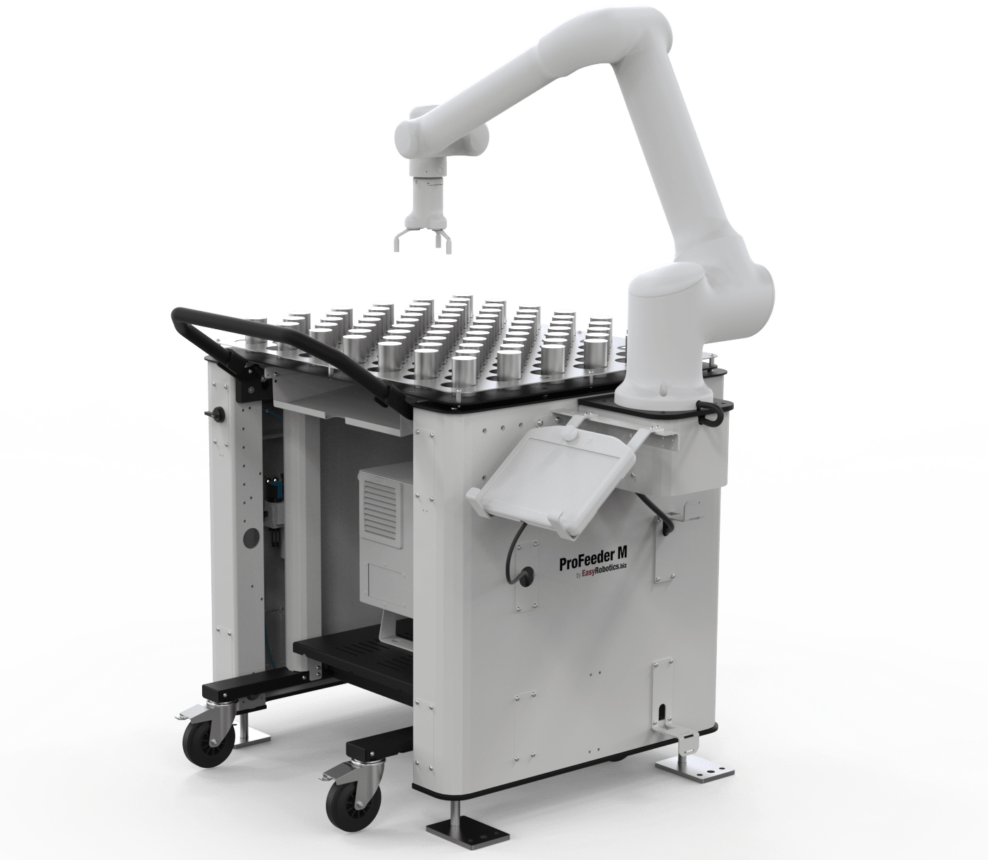

Tandem of collaborative robots and cells from EasyRobotics in the assembly automation

Maximum performance, excellent quality, high speed and, at the same time, minimized fixed costs – these are just some of the features, that cobot can provide in collaboration with robotic cells.

EasyRobotics has succeeded in creating innovative robot-cells that are characterized by versatility, advanced functionality, ease of use and aesthetic design. Each model of a robot-cell meets specific needs in automation process of various types of productions.

Why Profeeder Flex robot-cell is an ideal solution for assembly automation?

- Compact dimensions will save production space;

- Compatibility with all cobots on the market will make it possible to use the cell for various tasks;

- High maneuverability will ensure fast movement across the production area;

- The equipment set, with three tables mounted, guarantees convenience and speed of assembly process.

Equipping your production with a collaborative robot and a ProFeeder Flex is guaranteed to increase assembly speed and quality of finished products. The cobot, which assembles boards and other products, will ensure accuracy, productivity and high production speed, and the cell will ensure mobility, convenience, maneuverability and functionality.

By purchasing cobots and cells from EasyRobotics, you also get:

- Universal equipment that can be easily moved, reconfigured for various types of work;

- Fast return on investment due to significant reduction in fixed costs and labor costs;

- A significant competitive advantage that will allow you to produce and earn even more.

Implementation of collaborative robots and cells from EasyRobotics is the most efficient way to assembly automation. Find a regional distributor in your area or get advice directly from us, taking the first step towards increasing the profitability of your business.