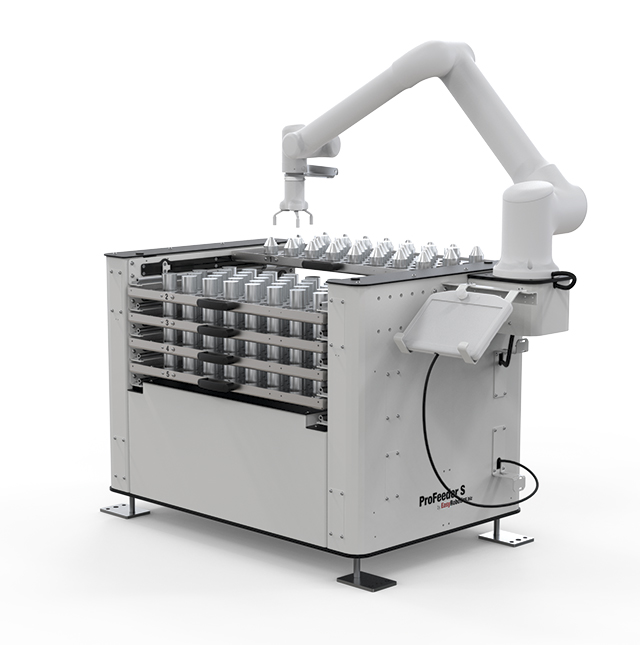

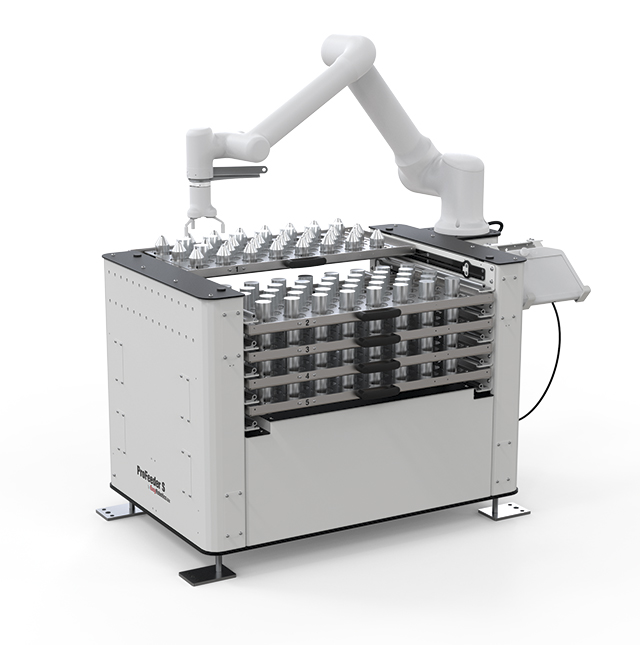

Profeeder S is a robust and cost effective robot-cell. The design is solid, unique and optimized by our engineers for gaining best performance in production automation.

High efficiency of this robot-cell is not the only advantage - it is also a simpe and cost-effective solution. The product can provide high capacity by five large trays with maximum load up to 150 kilo each. Each tray has a mechanical magnetic lock.