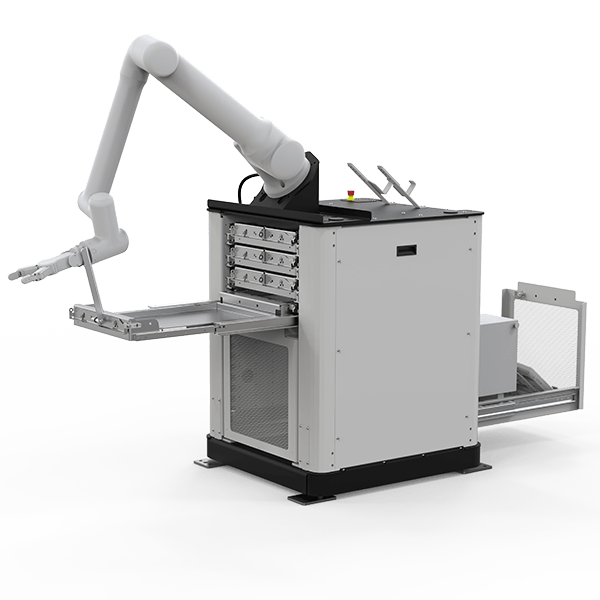

Compact robot is a complete "All in one" automation solution. You don't need any robot pedestals to use it, because cobot has to be mounted on the top of the robot-cell. Thanks to the universal mount - the cobot can be fixed at an angle of 45°, that provides 100% access to the entire surface of the built-in trays.

Features

- High compatibility. Compatible with all CNC machines and conveyor belts.

- Airlock or Mechlock system. Available with both Mechanical and Air locking systems.

- All in one solution. Self-sufficient automation solution that needs only cobot to be mounted.

- 45° or 0° cobot mount angle. The cobot can be mounted in two angles to make sure it has 100% access to all trays.

- 2 variants of tray-equipment. The product can be equipped either with 4 x 120kg trays for maximum 80mm parts height or with 3 x 60kg trays for 120mm height.

Product order overview

| Product order overview | ||

| PFC-3010-03 | PFC 3x 60kg tray w. Mechlock | H: 1050 mm, W: 770, L: 920, Wt: 345 kg, 3x 350x550mm tray area, 2,5mm deflection at 60kg/tray, Max part height 120mm, Mech-lock, T-Pad bracket, Compartment for controller, 45 degree angle for robot |

| PFC-3011-03 | PFC 3x 60kg tray w. Airlock | H: 1165 mm, W: 770, L: 920, Wt: 365 kg, 3x 350x550mm tray area, 2,5mm deflection at 60kg/tray, Max part height 120mm, Air-lock, T-Pad bracket, Controller compartment, 45 degree robot angle |

| PFC-3100-04 | PFC 4x 120kg tray w. Mechlock | H: 1050 mm, W: 770, L: 920, Wt: 405 kg, 4x 350x550mm tray area, 2,5mm deflection at 120kg/tray, Max part height 80mm, Mech-lock, T-Pad bracket, Controller-compartment, 45 degree robot arm angle |

| PFC-3101-04 | PFC 4x 120kg tray w. Airlock | H: 1165 mm, W: 770, L: 920, Wt: 425 kg, 4x 350x550mm tray area, 2,5mm deflection at 120kg/tray, Max part height 80mm, Air-lock, T-Pad bracket, Compartment for controller, 45 degree angle for robot |