|

Product order overview

|

|

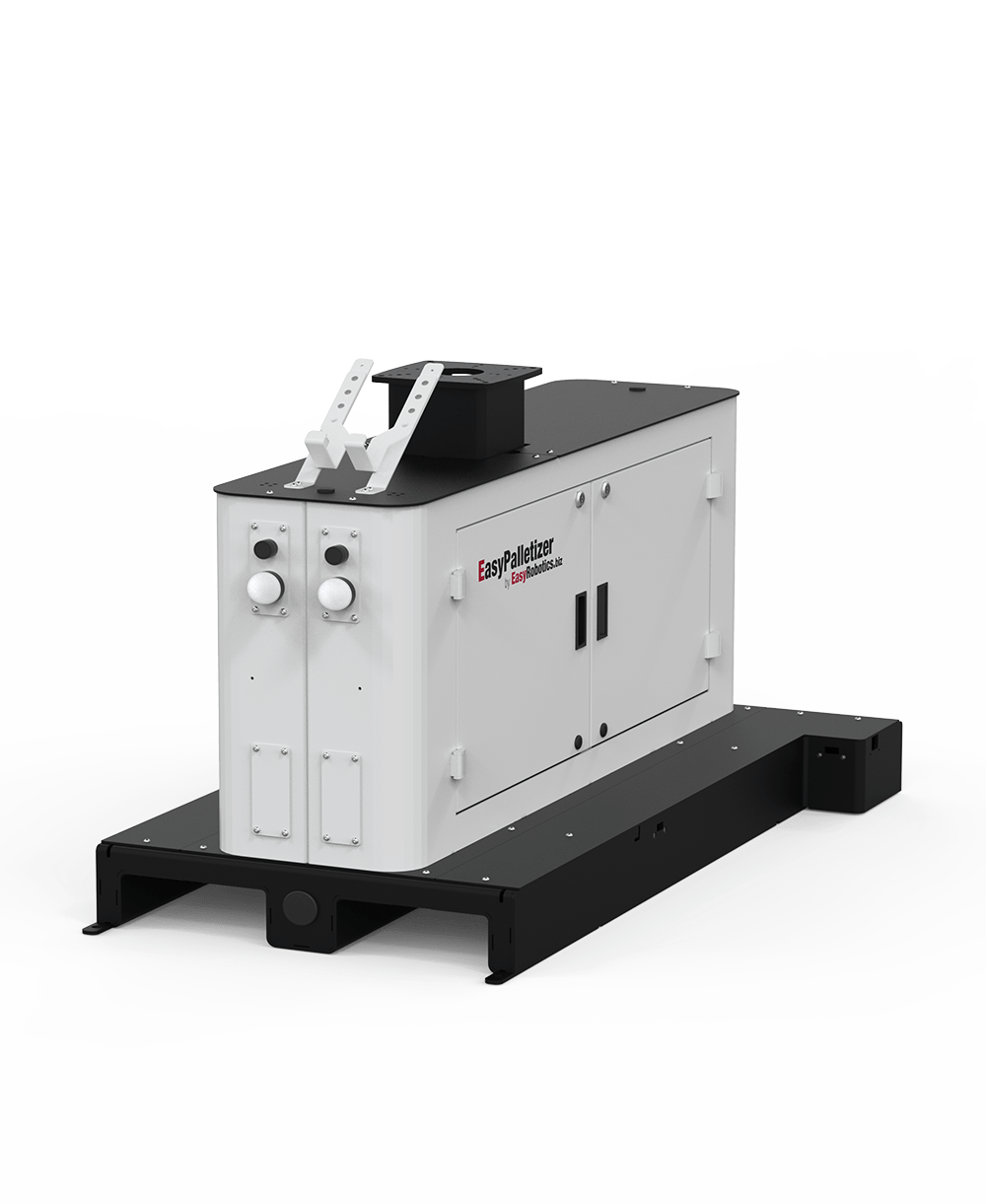

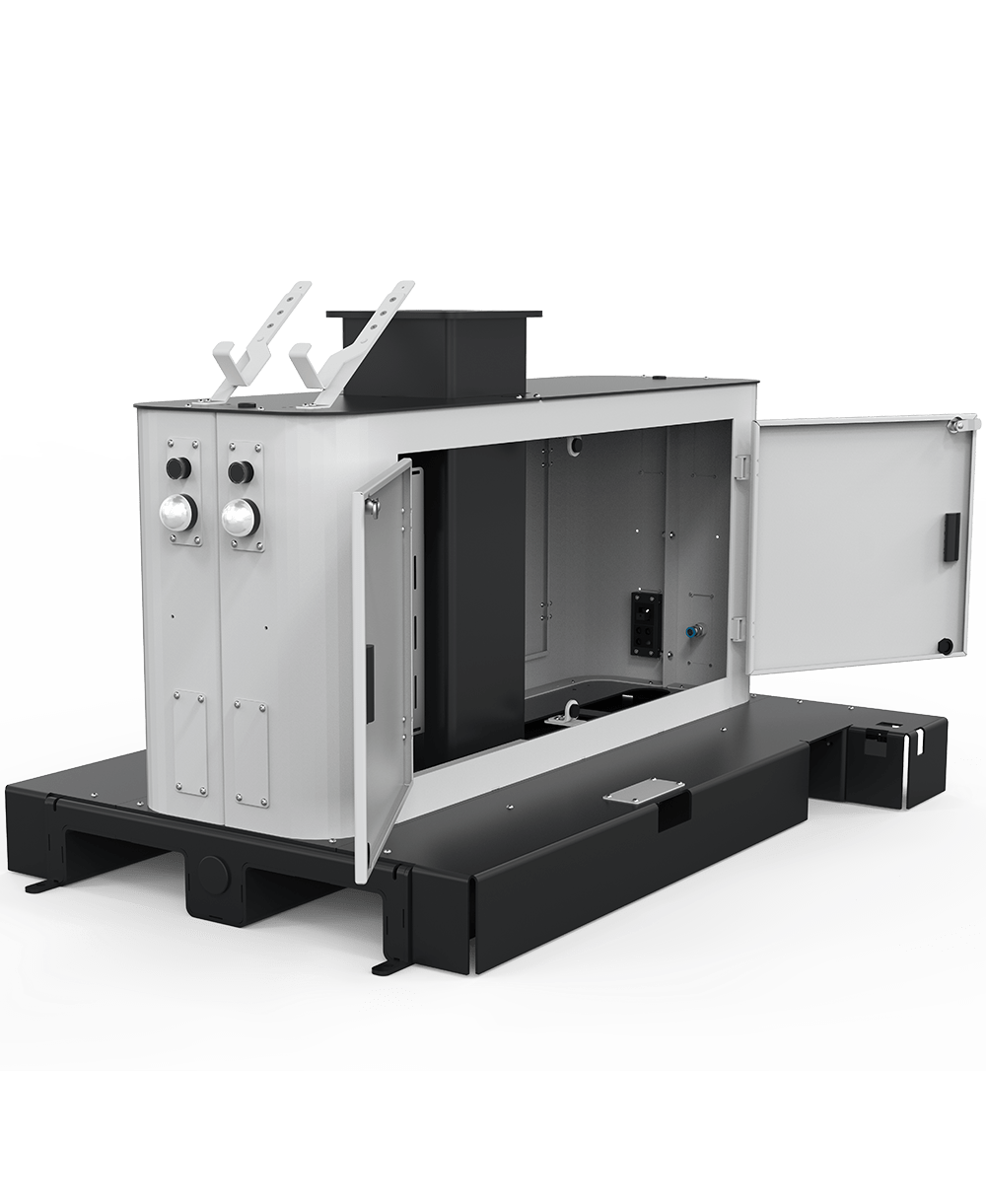

PT-1001

|

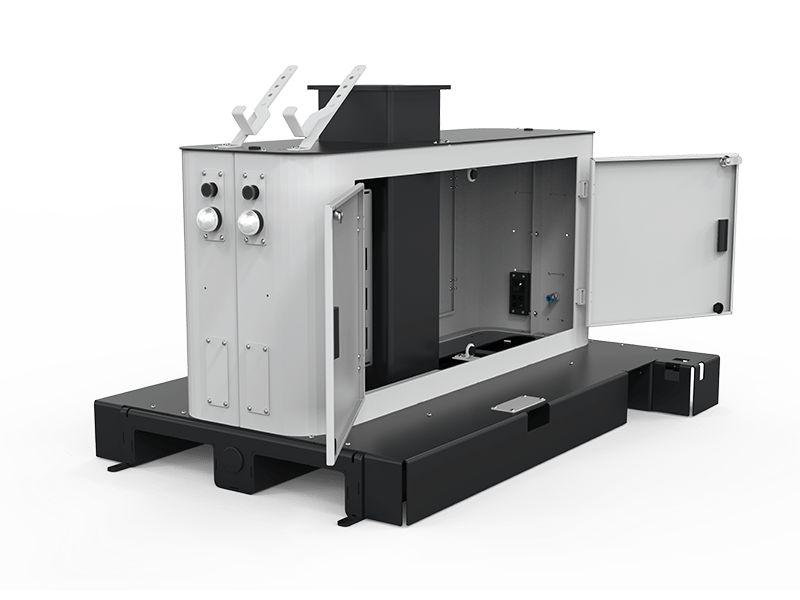

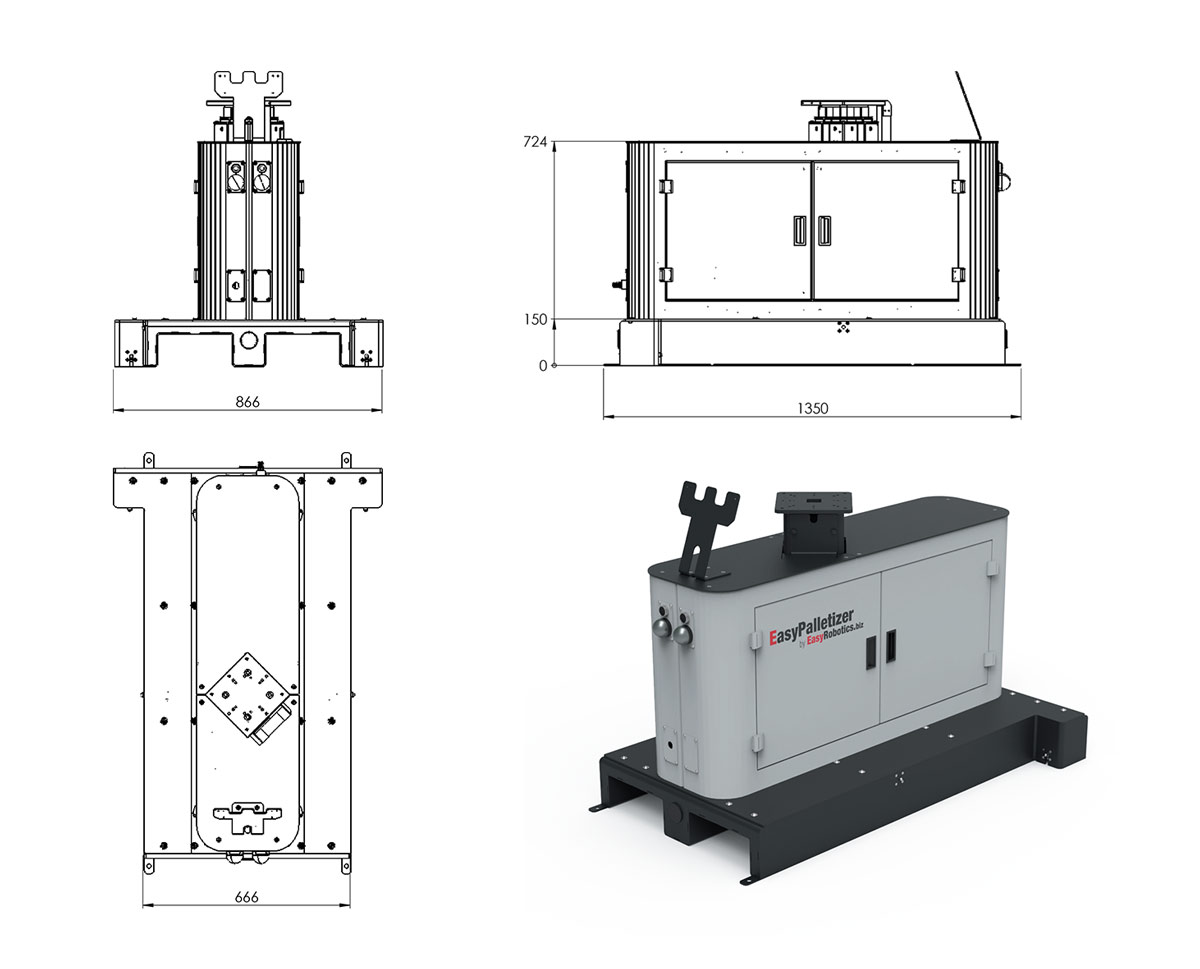

Palletizer One Base

|

H: 710 mm, W: 870, L: 1350, Wt: 190 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights

|

|

PT-1002

|

Palletizer One with fixed pedestal 835mm

|

H: 835 mm, W: 870, L: 1350, Wt: 200 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal

|

|

PT-1001-SST

|

Palletizer One Base Stainless Steel

|

H: 710 mm, W: 870, L: 1350, Wt: 195 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, AISI304

|

|

PT-1002-SST

|

Palletizer One with fixed pedestal 835mm Stainless Steel

|

H: 835 mm, W: 870, L: 1350, Wt: 205 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal, AISI304

|

|

PT-1010

|

Palletizer Two Base

|

H: 710 mm, W: 870, L: 1350, Wt: 195 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Extender Kit

|

|

PT-1011

|

Palletizer Two with fixed pedestal 835mm

|

H: 835 mm, W: 870, L: 1350, Wt: 215 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal, Extender Kit

|

|

PT-1013

|

Palletizer Two with fixed pedestal 1200mm

|

H: 1200 mm, W: 870, L: 1350, Wt: 220 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal, Extender Kit

|

|

PT-1010-SST

|

Palletizer Two Base Stainless Steel

|

H: 710 mm, W: 870, L: 1350, Wt: 195 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Extender Kit, AISI304

|

|

PT-1011-SST

|

Palletizer Two with fixed pedestal 835mm Stainless Steel

|

H: 835 mm, W: 870, L: 1350, Wt: 215 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal, Extender Kit, AISI304

|

|

PT-1013-SST

|

Palletizer Two with fixed pedestal 1200mm Stainless Steel

|

H: 835 mm, W: 870, L: 1350, Wt: 220 kg, For 2 pallets with 4 sensors and 2 configurable LED-lights, Fixed pedestal, Extender Kit, AISI304

|