Pharmaceutical automation with collaborative robots

Mass character, accuracy and sterility are the features of pharmaceutical production. This is where the collaborative robot is indispensable and pharmaceutical automation is needed.

A cobot is a robot for collaborating with humans. Equipped with feedback sensors, it will not harm people, and will stop when it hits an obstacle. This feature makes cobots safe and human-oriented. That is why in modern industry, manufacturers are increasingly opting for collaborative robots. It is stimulating the processes of pharmaceutical automation, because without requiring a separate work space, a cobot is highly efficient and relatively inexpensive.

The automation of a pharmaceutical line for handling blood samples has enabled Aalborg University Hospital to perform up to 3,000 tests per day.

In the modern realities of pharmaceutical production, the use of collaborative robots is not only possible, but also necessary. A dynamically changing life inevitably introduces changes in technological processes. The work of a classic pharmaceutical production line with integrated collaborative robots can be quicker and easier, then it used to be.

When building a production line to pharmaceutical automation standards, cobots can be tasked with:

- Unloading of products;

- Product marking;

- Dosage of substances;

- Analysis of biological material;

- Palletizing of ready products.

How cobots and cells from EasyRobotics can help pharmaceutical automation

EasyRobotics manufactures cells for collaborative robots. The concept of a cell can be associated with the concept of a workplace for a cobot. This is a robotic complex, the main goal of which is to optimize the work process as much as possible and reduce the time of one cycle without compromising the quality of work.

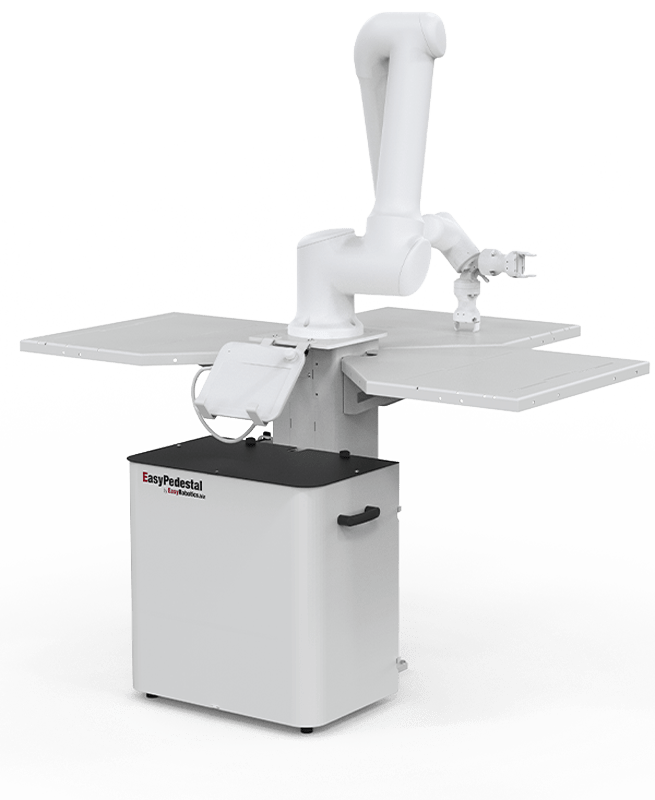

- The EasyPedestal is a cost-effective solution. It combines the qualities of stability and high compactness. Thanks to these qualities, EasyPedestal can be placed in almost any laboratory, even the smallest one. The platform is interoperable with other EasyRobotics products and can perform common tasks with them.

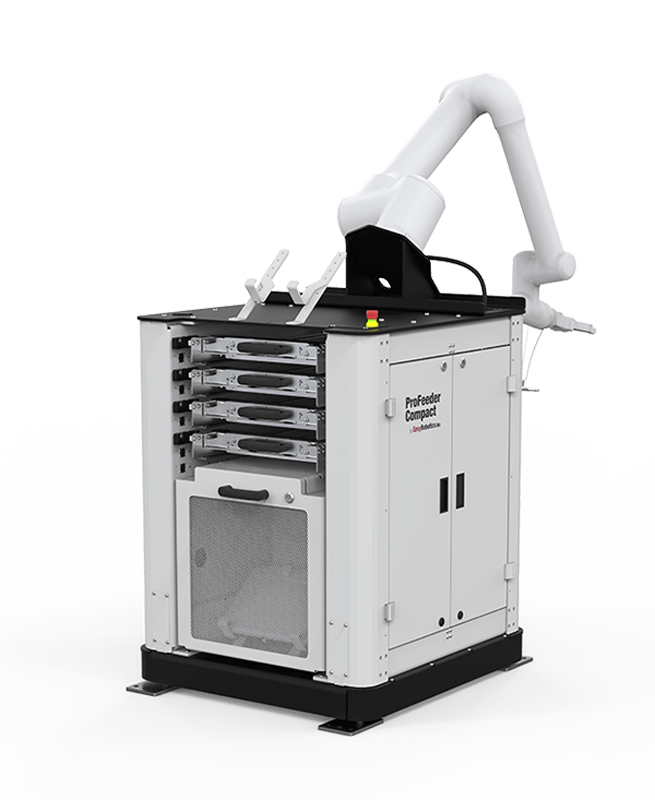

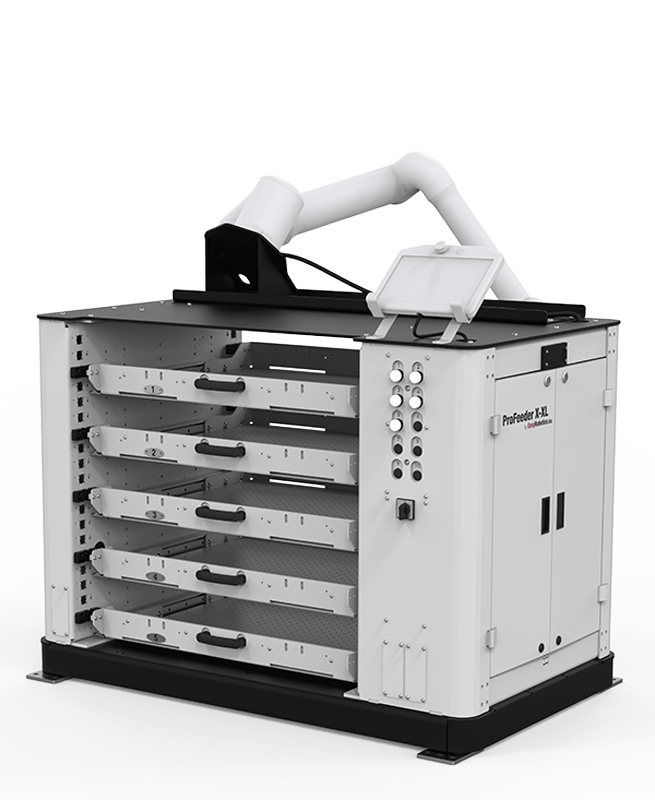

- The ProFeeder is a universal solution, that consists of a base unit with two trolleys and two centering trays, suitable for various shapes.

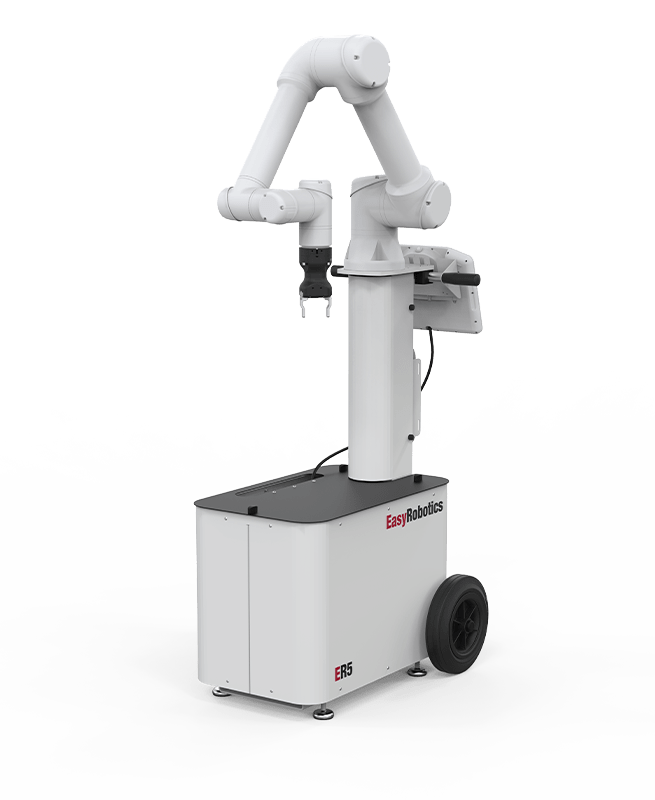

- The ER Work mobile station is a versatile and ultra-compact solution. It quickly integrates into automated and semi-automated production. The presence of built-in wheels allows ER Work to be used at once in several stages in turn, quickly moving the cell with the robot along the conveyor.

- The Easy Palletizer platform is a dedicated palletizing solution for finished products. Works accurately, quickly and safely. Conveyor compatible.

Mobility, flexibility, compactness and reliability are the main qualities of EasyRobotics cells. Cells are easily moved by one worker with standard hand loader, or *built-in wheels (optional on some models). Reconfiguring and preparing equipment for a new task on the line usually takes less than an hour.

The integration of EasyRobotics cells provides the following benefits:

- Saving production space due to compactness, mobility, versatility;

- Increase in labor productivity;

- Organization of additional shifts;

- Improving the quality of work, especially when performing monotonous operations that require tireless attention;

- Reducing industrial injuries;

- Ensuring reliable sterility of production;

- Fast return on investment.

To learn more about EasyRobotics products, visit other sections of the site. Detailed advice on the operation of the cells can be obtained from your local distributors, or by contacting us directly.