Automation of metal processing

Collaborative robots and cells from EasyRobotics are a good way not only to increase productivity and quality of finished products, but also to minimize the cost of manufactured products with the help of metal automation. As practice shows, when using robotic solutions, the speed of technological operations in metalworking (in comparison with manual maintenance) increases 2 times, and in relation to other types of industrial robots by 12-15%. At the same time, production costs are reduced by 36–40% by reducing the wage fund.

Other benefits of using collaborative robots and cells in metal automation:

- Easy setup and reconfiguration thanks to an intuitive control algorithm.

- A high degree of security is ensured by a carefully thought-out, reliable and simple layout.

- Payback in less than one year is achieved through significant increases in labor productivity and profitability. It becomes possible to introduce additional shifts, as well as reduce man-hours to 1 hour per shift instead of 8.

- Versatility of application. Collaborative robots and cells can be used to feed all kinds of CNC machines. Modern solutions are easily integrated into technological lines of varying degrees of complexity.

Robotic cells of the Profeeder series and their role in the automation of metalworking.

EasyRobotics Profeeder series – solutions for efficient metal production automation.

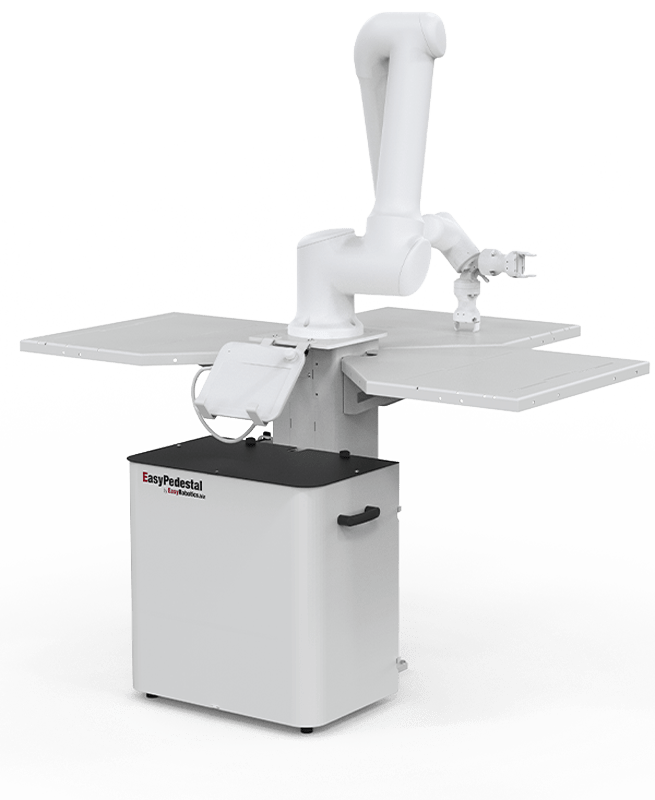

The offered cells are specially designed to speed up the work of cobots with CNC metalworking machines by automatically feeding them. An increase in the processing speed is realized by facilitating the operations of feeding blanks and taking finished products. All of the cells produced are compatible with collaborative robots of all brands supplied to the global market.

Depending on the purpose and tasks to be solved in metal automation, the following robotic cells can be ordered from us:

- Profeeder Table. A compact cell that can be used in various stages of welding, polishing, grinding, cutting, assembling or other types of metal processing. In the basic version, the handling is carried out using a pallet jack. Installation of heavy-duty wheels is possible on request.

- Profeeder Light. The robotic cell equipped with centering tray is designed for servicing CNC turning and milling machines. It can work with blanks or finished products weighing up to 10 kg.

- Profeeder Flex. Small-sized system with increased mobility are designed to service automated lines for assembly, cutting, grinding and other types of processing. Three versions are available: with one, pallet, with three or without working table.

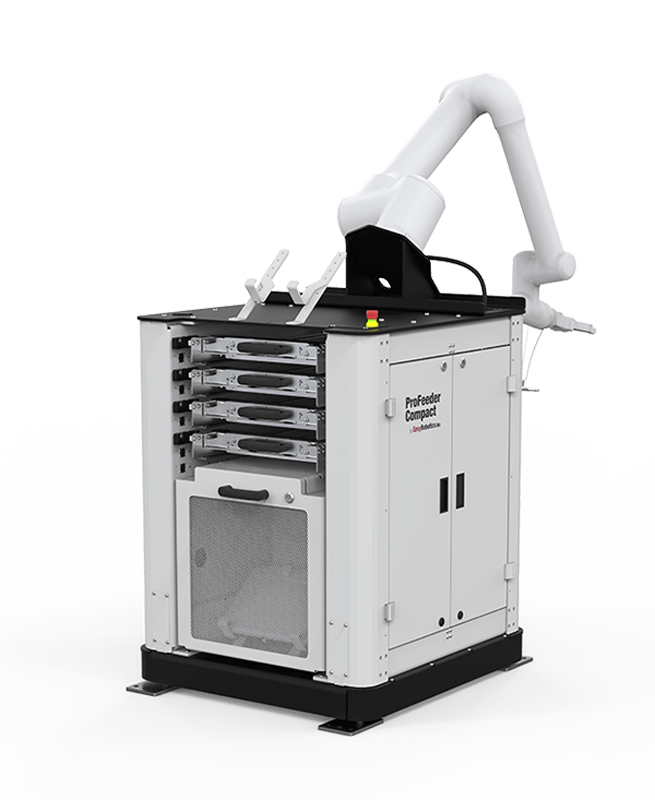

- Profeeder Compact. Small-sized console with 6 pull-out shelves for workpieces or finished products, equipped with mechanical or pneumatic locking systems.

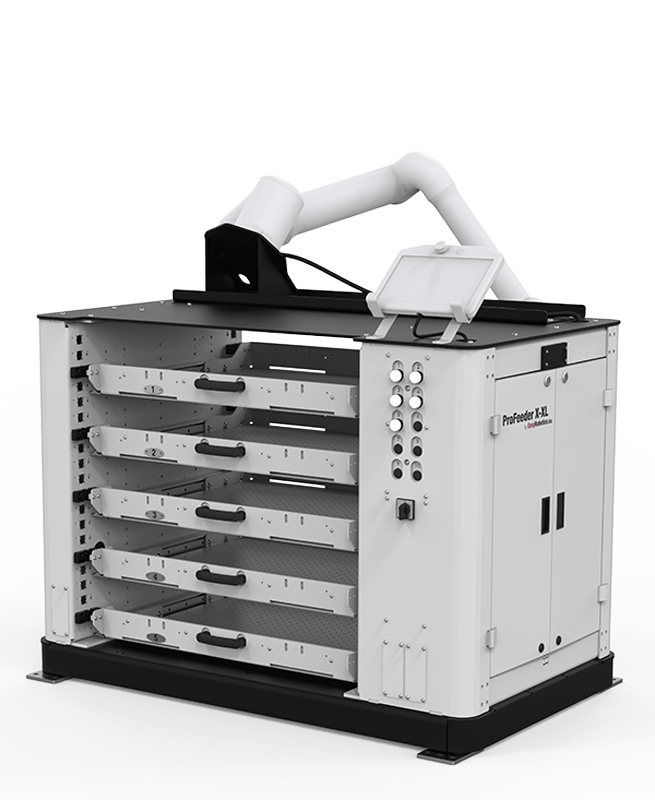

- Profeeder X. An advanced robot-cell with up to 10 stable pull-out shelves and ability to mount a collaborative robot on top of the console. Supports mechanical and pneumatic shelf locking systems.

- Profeeder. A robotic cell equipped with one basic module, 2 movers and two flexible automatically centered part trays.

Contact our regional distributor to find out more information about Collaborative Robots and EasyRobotics cells available in your region for efficient metal automation.