Production automation through the implementation of collaborative robots and robot-cells

Modern realities and the highest competition dictate to business representatives the requirements for continuous improvement. It concerns not only the quality of products, but also the speed of the production itself. In this regard, with the development of high technologies, manual labor is gradually being replaced by partial or complete production automation, which is quite justified. After all, a robot, unlike a human, can work continuously without loss of quality, perfectly coping with its functions.

But this is far from the only advantage that speaks in favor of introducing collaborative robots and cells into the production process. The latter are able not only to increase the speed and quality of manufactured parts and other products, but also to reduce labor costs. After the automation of production, the need for manual labor will decrease markedly. At the same time, you do not have to hire highly specialized personnel to manage and reconfigure equipment. The intuitive interface and intelligent control will allow even an inexperienced operator to cope with reprogramming.

Cells from EasyRobotics – the best solution for industrial automation

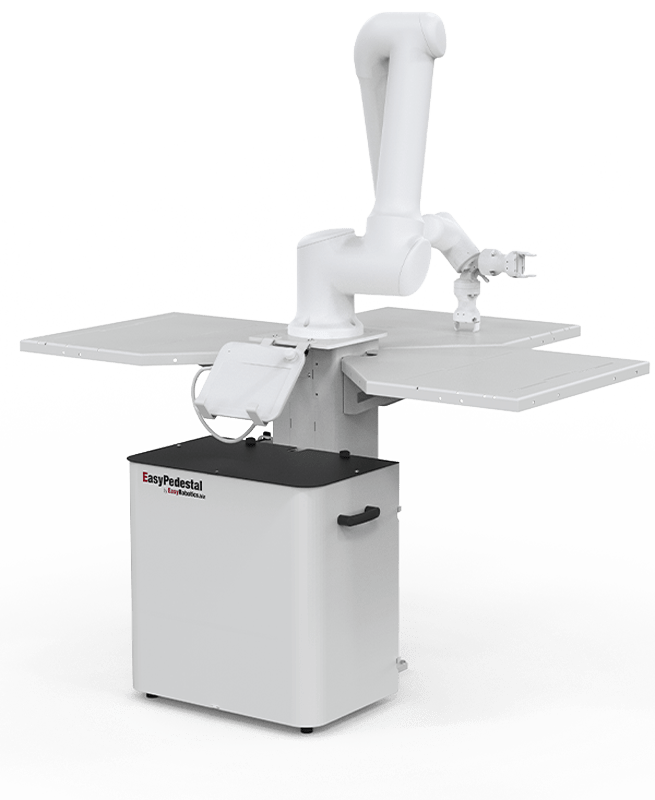

The variety, versatility and interoperability of EasyRobotics cells have made manufacturing automation affordable and easy. Regardless of the type of product being manufactured, everyone is able to choose suitable cells, which will become indispensable helpers in improving the quality and speed of production, assembling finished goods and even forming pallets.

You can automate production in whole or in part. In both cases, progress will not be long in coming: the introduction of collaborative robots and cells will inevitably have a positive effect at all stages of production.

What will you get as a result of production automation?

- Reducing the time to complete each production cycle and increasing the efficiency of work in general. Cobots working in tandem with multifunctional cells are able to ensure the continuity of the production process 24/7 without compromising product quality;

- Reduced injury rates. EasyRobotics equipment is designed with the highest possible safety in mind for personnel in the vicinity of the cell. When an obstacle appears in the path of a collaborative robot, it immediately stops and does no harm;

- The ability to move and reinstall. Robotic modular cells are compatible with all types of cobots, therefore, if necessary, they can be rearranged, combined, applied at different levels of production;

Reduction of the area occupied by production due to the compactness of the cells; - Quick return on investment by increasing productivity and reducing the cost of forming a wages fund.

The assortment of robot-cells from EasyRobotics is represented by the equipment necessary for the efficient production automation at all stages:

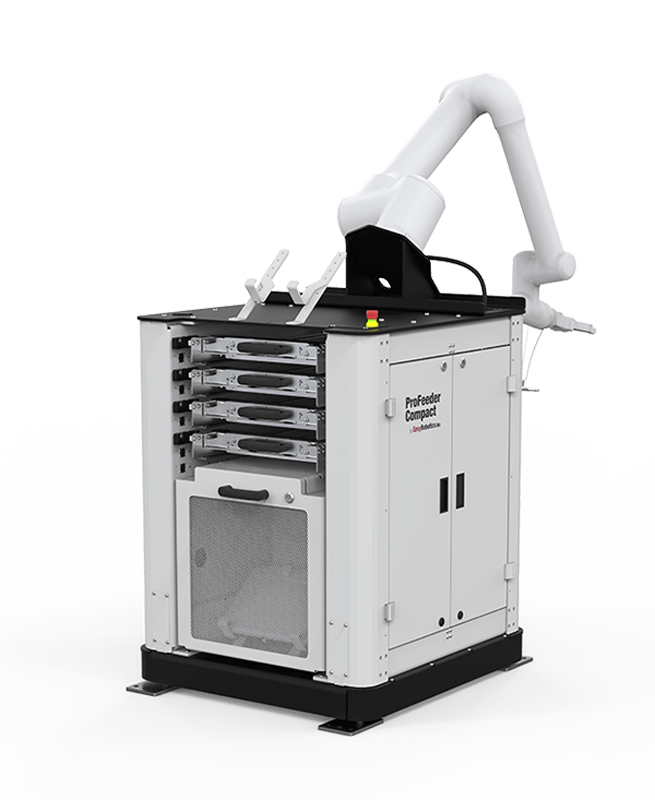

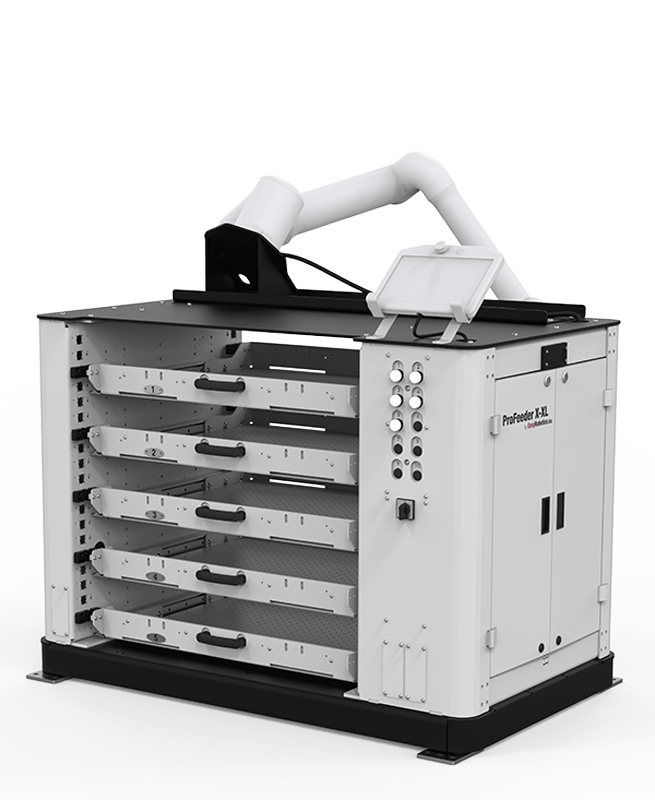

- Profeeder, Profeeder Light, Profeeder Compact, Profeeder X, Profeeder Flex and EasyDoor – these robot-cells and devices will be useful on lines powered by CNC machines;

- Easy Palletizer will help in handling automation by the formation of pallets up to 2.4 meters in height;

- Profeeder Table will reduce assembly time in any kind of production;

If you need help with production automation or have any questions regarding our products, don’t hesitate contacting directly with us or our regional representatives. You can get more detailed information about the work, customization, features of these robot-cells by browsing our website.