How to organize packaging automation using cobots and robotic cells?

The process of palletizing, like any other stage of production, has to occur as quickly as possible while maintaining proper quality. It is rather difficult to achieve the simultaneous presence of these indicators when using manual labor. Therefore, in order to achieve maximum productivity, it becomes necessary to organize packaging automation.

This is the only way to achieve a significant increase in efficiency, speed and quality. Due to the peculiarities of robotic technology and strict adherence to the specified parameters, you get absence of errors and high quality palletizing.

How can collaborative robots and cells help businesses to generate more revenue? In addition to increasing productivity, the profitability will grow due to a decrease in the wage bill, lower fixed costs and an increase in the volume of products produced.

Why the EasyPalletizer robotic platform is the ideal way for packaging automation?

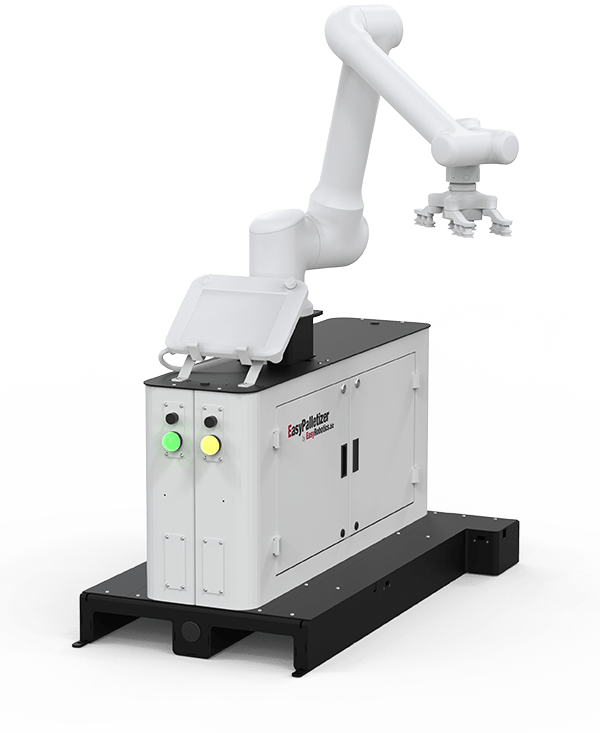

The main purpose of the EasyPalletizer platform from EasyRobotics is to automate the packaging process. The functional cell will save personnel from monotonous and hard work, leaving the operator with the ability to control and monitor.

What makes EasyPalletizer to stand out?

- If there is a need to change the parameters, the device can be quickly reconfigured by changing the size of the boxes and the stacking scheme;

- The platform is 100% compatible with all collaborative robots

- EasyPalletizer is completely safe for personnel. A collaborative attitude will not harm employees and reduce industrial injuries;

- The equipment can provide continuous packaging of products 24 hours a day. At the same time, as a result, ideally folded pallets will be formed due to the control function of pallet positioning provided by the developers;

- The cell does not require highly specialized programming knowledge. Even an inexperienced operator can make adjustments due to a simple and intuitive interface;

- EasyPalletizer is able to move up to 8 units of products per minute directly from the conveyor, placing them in a predetermined order at a height of up to 2.4 meters;

- The platform is suitable for packaging goods regardless of the type of product being produced;

In addition, the innovative multifunctional cell EasyPalletizer deserves attention due to following features:

- Compact footprint will help to keep free space in the workshop;

- Intelligent sensors help to position pallets and avoid industrial accidents;

- Excellent performance will ensure fast palletizing speed;

- The high quality of the cell itself will allow it to work without maintenance for many years.

It is also worth noting that EasyPalletizer can be supplied in different configurations, which depends on the needs of the business and preferred types of cobots.

You can get more detailed information about the product, as well as the terms of purchase from your regional dealers or directly from us. Help your business generate even more profits by organizing efficient packaging automation, and the result will not be long in coming!