Conveyor automation with cobots and robotic cells

How to improve productivity and increase the speed of production equipped with conveyor-type installations? The answer is conveyor automation! This can be possible by equipping the production line with cobots and robotic cells that can completely replace manual labor. Cobot automation will significantly increase the speed of each production cycle and the volume of ready products. It will simplify moving, labeling and palletizing of products by minimizing human involvement. The latter can only monitor the work of the robots, which takes place in automatic mode, according to pre-configured parameters.

The Role of Collaborative Robots and Cells from EasyRobotics in Conveyor Automation

Why is conveyor automation not only profitable, but also simply necessary in modern realities?

- Successful brand and reputation of the company is only a half of the success, and the integration of innovative technologies will play an important role in shaping the image;

- Due to the increase in the speed of execution of all stages of production, the volume of production will increase, and this will allow selling more goods, and increase profits;

- Reducing the need for manual labor will help save on wages. And it will also reduce the likelihood of injury and increase the safety of production in general;

- Cells from EasyRobotics are multifunctional, versatile and mutually compatible. Conveyor automation allows this equipment to be used in tandem with any collaborative robot brands very effective. By purchasing several robot-cells, you really get much more than just robot stands. Indeed, thanks to the extended functionality, they can replace equipment for various purposes on different production areas.

No less attention should be paid to the mobility, lightness and compact dimensions of the cells. These parameters allow the use of the equipment even in very small production halls, including workshops and local productions.

What can EasyRobotics mobile platforms and cells be used for?

They can work with any type of conveyor. This can be the production of food, metal works, pharmaceutical and other products. The cells are delivered 80% assembled – the process of setting up and installing the cobot does not take more than an hour, and the intuitive interface allows you to quickly set up the cobot to work with any type of product on the conveyor. With just a few hand movements of the operator, the cobot is ready to operate with the cell.

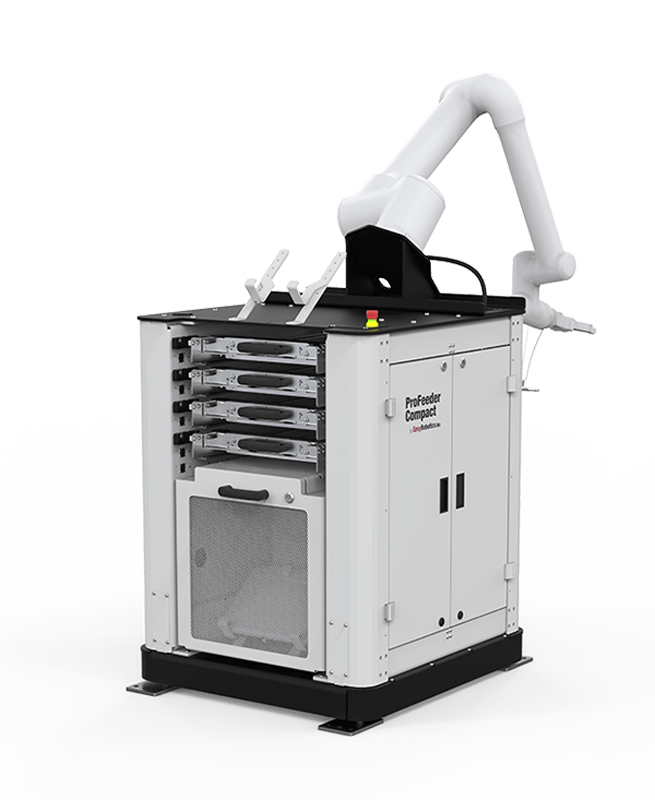

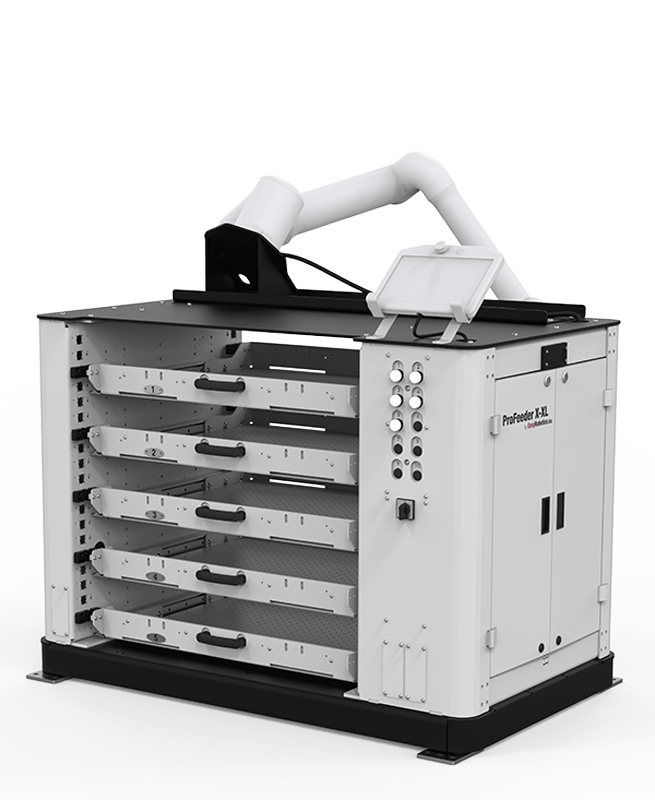

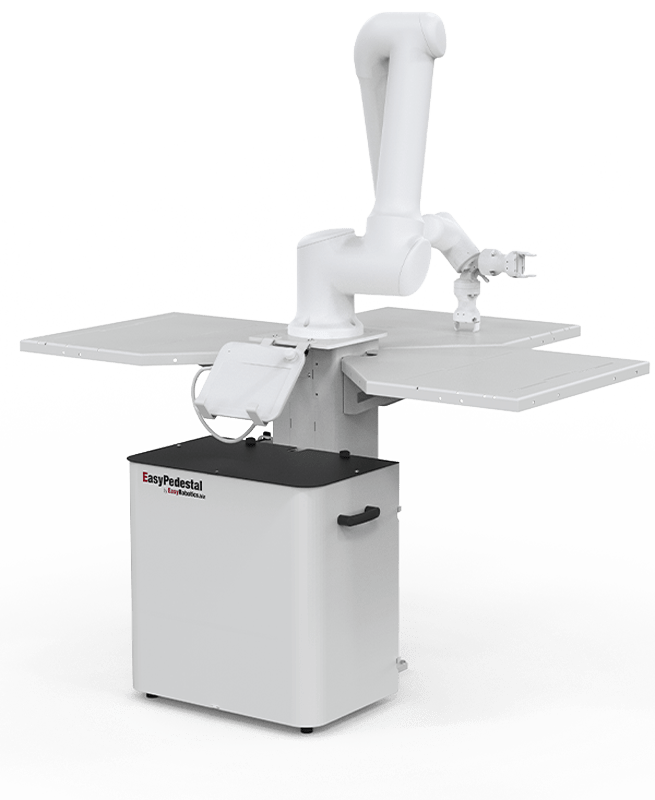

Smart cells from EasyRobotics are represented by:

- The ProFeeder system that allows you to quickly move and store parts weighing up to 10 kg, increasing productivity up to 2 times;

- The EasyPalletizer platform, which helps to form perfectly flat pallets, transferring products to them directly from the conveyor, moving up to 8 units of products per minute, palletizing goods to a height of 2.4 meters;

- Mobile platform ER Work, able to quickly move along the conveyor, switching between different tasks

- The EasyDoor automatic door opening system, which can speed up the machine tending process of CNC machines and reduce the cycle time for feeding of each part.

Help your business to generate even more profit, and we will assist you with this by offering the most profitable and suitable solutions for conveyor automation. For more information please contact your local distributor.